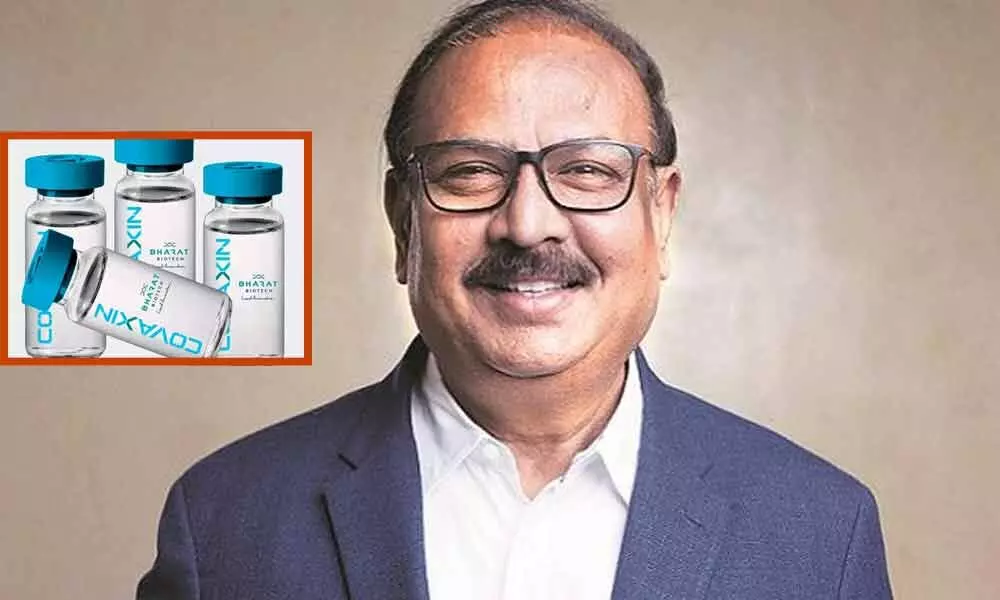

Bharat Biotech set to achieve 700 mn doses

Bharat Biotech set to achieve 700 mn doses

At present, the company has four BSL-3 facilities - two in Hyderabad and two in Bengaluru

New Delhi: BIOTECHNOLOGY major Bharat Biotech's BSL-3 (Biosafety Level-3) facilities will play a pivotal role in empowering the company's plans to ramp-up production of India's first indigenously developed Covid-19 vaccine.

Accordingly, the biotechnology major plans to produce 700 million doses of Covaxin per annum. The vaccine is regarded as one of the safest in the world and highly efficient against the UK, SA, Brazilian and the new Indian double mutant strain of Covid-19 virus. In a conversation with IANS, Krishna Ella, Chairman and Managing Director of Bharat Biotech International said the capacity expansion process has been initiated across multiple facilities since early 2021.

Presently, the company manufactures 20 million doses per month of Covaxin which are supplied to the Ministry of Health for the national vaccine rollout. "Manufacturing scale up has been carried out in a stepwise manner across multiple facilities at Hyderabad, and Bangalore," he said.

"Inactivated vaccines, while highly safe, are extremely complex and expensive to manufacture, resulting in lower yields when compared to live virus vaccines." Notably, Bharat Biotech is able to expand Covaxin manufacturing capacity mainly due to the availability of four new specially designed BSL-3 facilities.

In industry parlance, a BSL-3 facility is equipped to safely handle infectious biological pathogens in the highest stringent environmentally controlled manufacturing facility.

At present, the company has four BSL-3 facilities - two in Hyderabad and two in Bengaluru. "These facilities have been repurposed due to a strong pre-existing expertise in development of viral vaccines and know-how applied to manufacture, test and release the highly purified inactivated viral vaccine." The company has recently entered into a 'Master Collaborative Agreement' (MCA) with CSIR-Indian Institute of Chemical Technology (CSIR-IICT), to collaborate on the development of novel platform technologies in developing a synthetic process route for adjuvant molecule 'TLR 7/8' for Covaxin.

Bharat Biotech uses a proprietary adjuvant Algel-IMDG, that has now proven to be a safe and effective adjuvant, especially to stimulate memory T cell responses. The synthesis and manufacture of the IMDG component has been successfully indigenised and will be manufactured at commercial scale within the country. This is the first instance where a novel adjuvant has been commercialised in India. Besides, the company has secured long term components, packing materials and single use consumables supplies for the manufacturing ramp-up. To further increase bulk capacity Bharat Biotech has entered into agreements with Indian Immunologicals (IIL) to manufacture the drug substance for Covaxin. "The technology transfer process is well underway and IIL has adequate capabilities to manufacture inactivated viral vaccines at commercial scale and under required 'GMP' standard."

"We are also looking forward to getting into manufacturing partnerships in other countries." Currently, Covaxin has received 'Emergency Use Authorisations' in several countries across the globe with another 60 in process.