Exploring the Impact of Automation in Reducing Food Waste Across Supply Chains by Mohan Valluri

Food waste has become an essential concern due to the increasing concern for sustainability practices across the globe especially in the supply chain.

Bengaluru: Food waste has become an essential concern due to the increasing concern for sustainability practices across the globe especially in the supply chain. Applications like real-time data analytics, artificial intelligence, and robotics are now playing the roles of how businesses address this issue. Through integration, efficient resource utilization and reduction of waste, these innovations are putting in place best practices in sustainable food production and delivery.

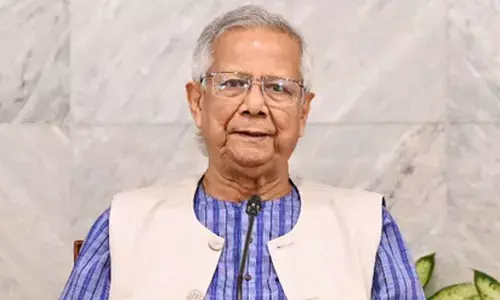

Being a leader in the Consumer-Packaged Goods (CPG) sector, Mohan Valluri said, “In my experience working with automation technologies, I’ve seen firsthand how the integration of real-time data, AI, and robotics can drastically minimize waste, not only enhancing sustainability but also improving operational efficiency.” With several years of industry experience, he has led strategic growth initiatives focused on leveraging AI, robotics, and data analytics to drive efficiency, innovation, and sustainability within supply chain and manufacturing operations. He is also an active member of the National Aerosol Association (NAA) and the Private Label Manufacturers Association (PLMA).

Real-time data analytics is one of the areas through which automation is enhancing sustainability in food supply chains. Predictive analytics can also help to better manage production and avoid situations when industrialists end up with too much inventory that spoils before it is sold. This dynamic approach enables organisations to satisfy demand without forecasting it, a weakness that has always characterised supply chain systems. Automations is as important in logistics as it has been in other areas of the supply chain. Valluri highlighted that with the with the help of AI systems and sensors, it can be guaranteed that products will be stored and transported in the right conditions thus increasing shelf life and minimizing the risk of spoilage. For example, automated inventory systems can help in monitoring the location of products at any one time and using this information to change the storage or transportation frequency to ensure that products do not go bad. All these capabilities are important for developing supply chain responsiveness to address the increasing call for sustainable solutions.

At Alamance Foods, where he implemented measures to cutting on food wastage, automation has been a major boost. By implementing robotics technology in the production line, he reduced wastage of packaging materials, and in the process use raw materials more efficiently. Moreover, the implementation of AI-based systems has enhanced the management of resources, so that the consumable items are used more effectively. These changes have been significant and allowed for sustainability goals to be met as well as increasing organizational efficiency. Another key area where he has noted significant impact of automation in supply chain is in the effort to attain zero-waste. The monitoring of material flows in real time and the consequent adjustments to the material flows have allowed his organisation to minimize overproduction risks, thus adapting processes to more responsible consumption. This shift not only lowers emissions but also brings down the environmental impact of producing food, a vital factor in tackling food wastage globally.

Valluri has worked to achieve a 15% saving in food waste at critical stages of the supply chain. This has been made possible using automation and predictive analytics to ensure that production is scalable and at the same time minimal wastage is done. This accomplishment demonstrates that automation can serve to meet business and environmental objectives at the same time. Another area of focus has been on improving on packaging solutions. Advancements in robotics and sensors have enabled him to create better packaging that can help increase the shelf life of products by 20%. The innovations assist in cutting costs of spoilage during storage and transportation, hence, making the supply chains more sustainable.

It is therefore expected that future of food production and distribution will continue to embrace automation technologies. They have found that as AI and predictive modelling advance, the ability to build better and more effective supply chain systems improves as well. It is, therefore, possible for the food industry to achieve meaningful goals in the overall global environmental situation while remaining profitable if the issues of operational efficiency and sustainability are considered in the right perspective.

Finally, automation is not merely a way to improve the productivity of a business, it is a driver of change. Automation is providing a new level of sustainability in terms of food production and distribution. The projects that Mohan Valluri has done in this field demonstrate how technology can be used to build better supply chains for food that are not only better but also more sustainabl