At Yelankha's Rail Wheel Factory, An Oxygen Cylinder Bottling Plant Will Be Inaugurated Soon

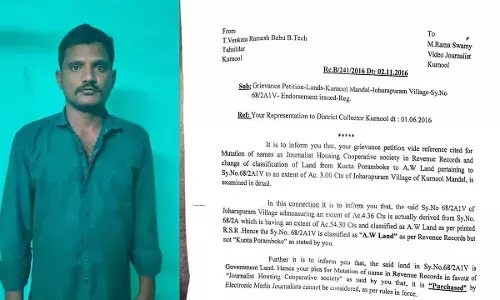

The Oxygen Cylinder Bottling Plant that will be launched at Rail Wheel Factory in Yelahanka shortly (Photo/newindianexpress)

- The Rail Wheel Factory (RWF) in Yelahanka, Bengaluru will soon open an Oxygen Cylinder bottling factory capable of producing 106 cylinders of Medical Grade Oxygen per day.

- The relocation, which had been planned for three months, recently received a much-anticipated Compressor from Italy.

To prepare for the expected third wave of the pandemic, several states are taking a variety of steps to combat the deteriorating situation that occurred in the second wave, the Rail Wheel Factory (RWF) in Yelahanka, Bengaluru will soon open an Oxygen Cylinder bottling factory capable of producing 106 cylinders of Medical Grade Oxygen per day.

The relocation, which had been planned for three months, recently received a much-anticipated Compressor from Italy. The whole project cost, along with the compressor, pipelines, testing equipment, and several other items, are estimated to be around Rs 75 lakh. The RWF provides Indian Railways with wheels and axles.

Rajiv Kumar Vyas, RWF's General Manager stated that in anticipation of the arrival of the third wave, RWF has prepared and improved its oxygen plant. This will serve the railway hospitals within RWF and the Bengaluru Division, as well as state government and private hospitals, as needed.

RWF operates a plant that produces industrial-grade, high-purity oxygen for internal usage. The business opened in 2009 and is now fully operational, melting steel and preparing train wheels in its Wheel Shop. During the second wave of the pandemic, RWF received multiple requests for medical oxygen.

The General Manager mentioned that the oxygen produced by RWF is in a gaseous condition, with a pressure of 12 kilogrammes per square centimetre at the exit. The medical oxygen cylinders must be filled with 150 BAR oxygen gas. The oxygen will now be compressed to a pressure of 150 BAR utilising the air separation process method, using a specific oxygen compressor for which an order has been placed in Italy. It has only recently come. So far now, the plants are accompanying manifolds with bottling equipment, and is now finally being implemented.

Meanwhile, the bottling plant will be able to fill around 6 cylinders each hour, with two shifts per day. While the factory has previously received approval from the Nagpur-based Petroleum and Explosives Safety Organisation (PESO) and the state government.